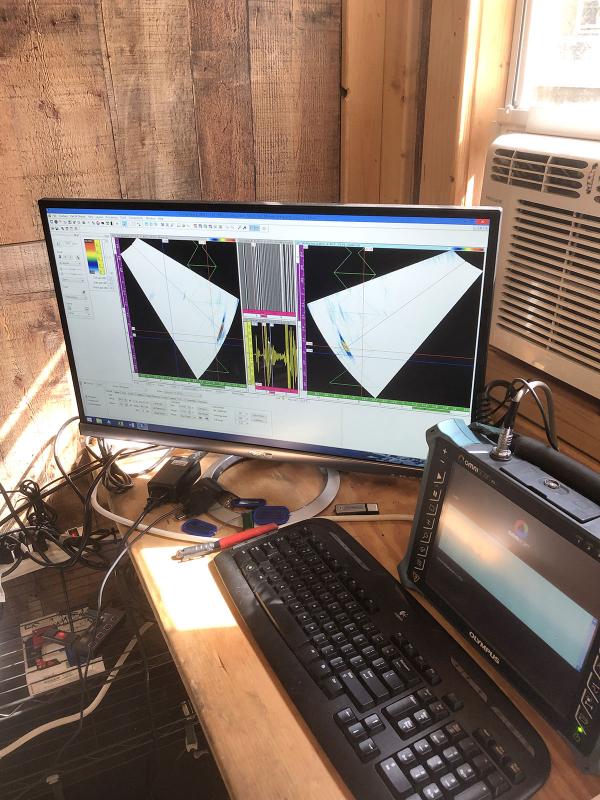

Sound NDT Solutions is a recognized industry leader in Phased Array Ultrasonic Testing services. We specialize in cost-effective, code-compliant weld examinations of pipe and pressure vessels and fabricated items utilizing the latest PAUT technologies and techniques via manual scanning methods or fully automated, cutting-edge AUT systems. Our PAUT specialists are highly trained and competency-certified and backed by our ASNT Level III subject matter experts. As with all of our NDT services, SNS can deliver its PAUT services at our clients’ job sites via our mobile field services labs or at our in-house NDT laboratory facility in Conroe, Texas.

Phased array technology offers the following benefits:

- Software control of beam angle, focal distance, and spot size

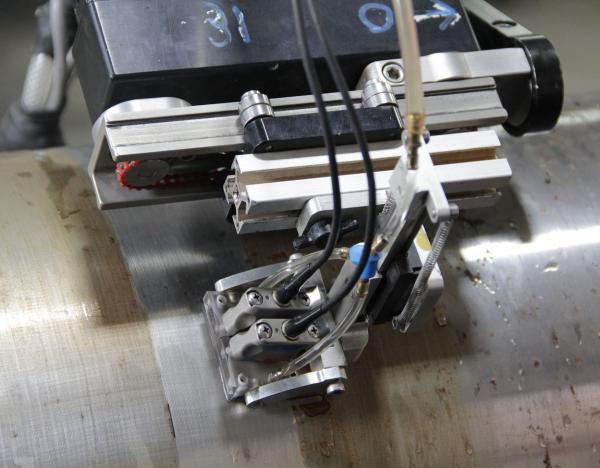

- Multiple-angle inspection with a single, small, electronically controlled multi-element probe

- Greater flexibility for the inspection of complex geometry

- High-speed scans with no moving parts

- Optimized signal-to-noise ratio

- Probability of detection (POD) is increased due to improved data displays

- Only 0.500″ (12mm) clearance required for probes to circumference weld

- Accurate locating and sizing of weld defects reduces repair excavation size

- Consistent defect characterization for technicians

- Recordable encoded image of weld for client viewing

- A permanent electronic record of the inspection

Advantages of Phased Array Ultrasonic Testing

PAUT allows testing in areas and under conditions that are difficult, expensive, or impossible with conventional NDT methods. Advantages of PAUT include:

- Faster and more reliable inspection

- Software-based control over ultrasonic beam characteristics

- Control of aperture size, steering (refracted) angle, and focusing position

- Electronic scanning (raster) without moving probe

- Simultaneous inspection with a multitude of angles using one probe

- Better inspection of complex geometries and limited access area

Why Phased Array UT?

In addition to its superior imaging capabilities, PAUT offers significant cost savings over other volumetric NDT methods (i.e., RT and conventional UT) in terms of data collection, analysis, and reporting productivity. The most significant advantage of using PAUT in lieu RT is time savings—which in the high production worlds of construction and fabrication equates to money. Because ultrasonic testing doesn’t require radioactive sources, there is no need to clear the work area to protect adjacent crafts from ionizing radiation emissions. This means PAUT examinations can be conducted while adjacent activities continue uninterrupted, i.e., ongoing welding production and timely delivery of results. Unlike radiography, UT data can be collected and analyzed in real time and results shared immediately—no need for x-ray film processing and interpretation. In addition, while RT presents data in two dimensions, PAUT provides three-dimensional images, offering superior flaw information, providing better defect sizing accuracy and characterization information and repair information. Once flaws are accurately identified, characterized, and sized, SNS's Level III subject matter experts can assist with appropriate code evaluation and mitigation measures, and work with crafts on repair and welding strategies.

Contact Us

Contact Us +1 (936) 760-7774

+1 (936) 760-7774