Magnetic Particle Testing (MT) is a highly effective, low-cost NDT method used primarily to detect surface and near-surface discontinuities in ferromagnetic materials. The process requires magnetizing the part to be inspected, and then applying ferromagnetic particles to the surface, which are then attracted to the leakage fields in the component. These particles accumulate at the leakage area to give a visible indication to the presence of the discontinuity.

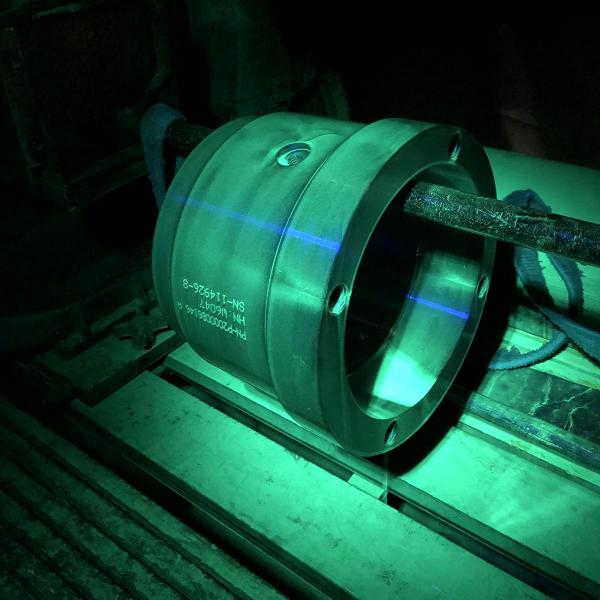

Sound NDT Solutions offers multiple magnetic particle inspection techniques, depending on client applications and requirements, all delivered by our team of highly trained and fully certified NDT Specialists. Our MT services can be deployed at client work sites utilizing portable inspection equipment, or at our full-service NDT laboratory facility in Conroe, Texas, utilizing our Magne-Tech fluorescent magnetic particle inspection work stations for customers that require high-production, multiple-component inspections.

MT takes advantage of the fact that magnetically susceptible materials are attracted to magnetic fields. The inspection process induces a magnetic flux field into the component to be inspected through direct or indirect magnetization, utilizing permanent magnets, electromagnetics, or electric currents. The field is applied to a level where discontinuities, or interruptions in the normal physical structure of the material, cause distortions in the magnetic field. The distortions cause localized fields, termed “flux leakage fields”, to emerge from the surface of the component being inspected. Small, finely divided ferromagnetic particles are applied to the surface of the area of interest and are attracted to the leakage fields. These magnetic particles accumulate at the leakage area to give a visible indication to the presence of the discontinuity.

MT can be used to detect a number of different types of surface breaking and near-surface discontinuities and can be performed on raw materials, in-process materials, or finished materials such as cast, rolled, and forged products, welds, billets. MT can also be performed on in-service or disassembled products. Magnetic particle inspection is a reliable and highly sensitive testing method. It is fast and relatively simple to perform and has few limitations as to the size and shape of the part being inspected. Set-up and preparations costs are minimal when compared with other conventional NDT methods such as Liquid Penetrant Testing (PT), which requires stringent cleaning before testing.

Contact Us

Contact Us +1 (936) 760-7774

+1 (936) 760-7774